this post was submitted on 10 Mar 2025

23 points (100.0% liked)

Electronics

2300 readers

28 users here now

Projects, pictures, industry discussions and news about electronic engineering & component-level electronic circuits.

Rules

1: Be nice.

2: Be on-topic (eg: Electronic, not electrical).

3: No commercial stuff, buying, selling or valuations.

4: No circuit design or repair, tools or component questions.

5: No excessively promoting your own sites, social media, videos etc.

Ask questions in https://discuss.tchncs.de/c/askelectronics

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

Woah those are some cool properties, I wonder how hard these gears would be to manufacture at home? I'm looking at implementing my own custom gear reductions in servos but I don't think my 3d prints will mesh well enough or withstand long usage

@Gronk @WaterWaiver

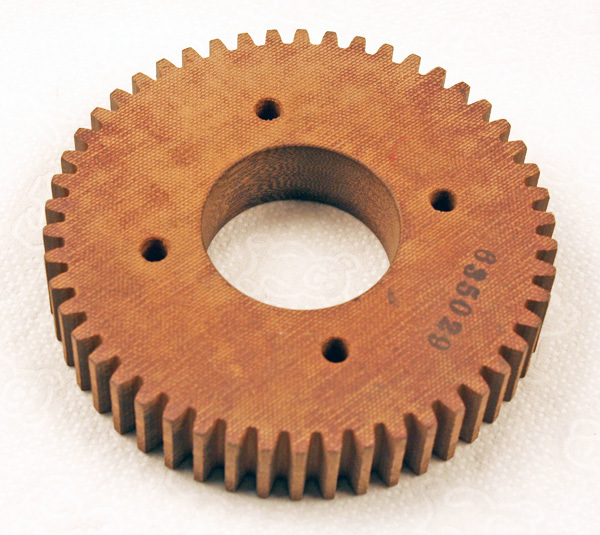

I printed 2 gears for my 7x12 lathe out of a filament from Igus.

https://www.igus.com/product/20322?artNr=I190-PF-0175-0750

Been in use for over 5 months and from inspection are in good shape. Quieter and unlike the originals durable. One is sacrificial and will shear if the lathe jams. When I jammed it it loaded the motor pretty heavily then let go so it did work. Some replace that gear with a metal one but I wanted the sacrificial feature so I do not blow the motor and speed control.

You need a heated chamber and they recommend heat treating it before use which I did not do since I was not certain it would not change the dimensions.

They have a few other filaments that are also useful. I went to this after multiple attempts to 3d print delrin. Even made a wood bed and finally gave up.

It's not cheap but I still have over 90% on the reel left after printing 3 gears.

There are some youtube videos of people machining them (sadly my browser does not support smell). Looks like you treat it like any other solid material: hobb or mill the teeth. This is much more expensive than 3d printing.

You might be surprised by your 3d printed gears. If you keep the detail size large they work really well, but backlash is definitely an issue.