https://www.canolacouncil.org/about-canola/processing/

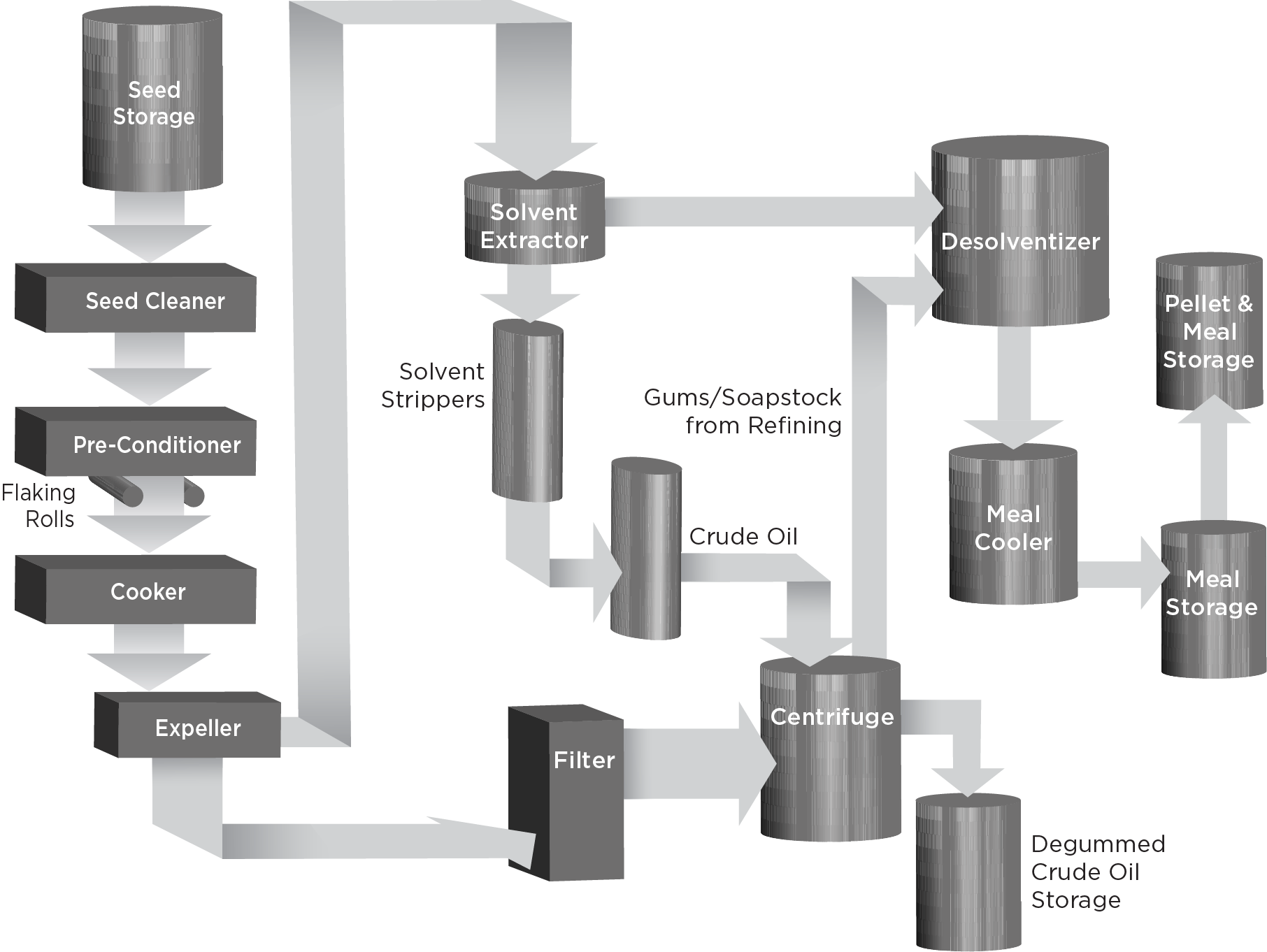

Traditional processing - Most Canadian companies use the same method to process canola seed.

Cleaning

First canola seed is thoroughly cleaned to remove “dockage” – weed seeds, stems, pods and other materials that may be picked up as canola is harvested.

Heating and flaking

Canola is heated and flaked before extraction so more oil can be released. The temperature is slightly raised in grain dryers to prevent shattering. The seed is then passed through rollers to gently rupture the cell walls and flake the seed to just the right thickness.

Seed cooking

Next the flakes go through a series of heating drums or stack-type cookers. This ruptures more cells and optimizes the viscosity of the oil and moisture of the flakes for the processes ahead. Cooking also prevents the breakdown of products that could affect quality.

Pressing

The cooked flakes then go through a series of screw presses or expellers for a mild pressing. This process removes most of the oil and compresses the rest of seed into cake.

Solvent extraction

To remove the remaining oil, the presscake is put into an extractor and saturated with a solvent called hexane. The solvent percolates through the cake and carries nearly all of the remaining oil away. The hexane is then removed from the oil and solids, reused and recycled.

Further oil refining and processing

Crude canola oil is further refined to improve colour, flavour and shelf life. Water and organic acids may be used to remove lipids, gums, free fatty acids and fine meal particles. Color pigments are removed by passing oil through a filter containing natural clay (a process sometimes called “bleaching,” although no bleach is used). The final step is to remove any unpleasant odours or compounds with steam distillation.

At this point, canola oil is ready to be packaged and sold as cooking oil, or further processed into a wide range of consumer and commercial products.

Highlights that stand out to me -

Heated, Heated, Heated, Hexane, Organic Acids, Bleaching, Deodorization (removes oxidation smell).

You skipped the basic treatment (with NaOH)

20th century foods. Not for me.