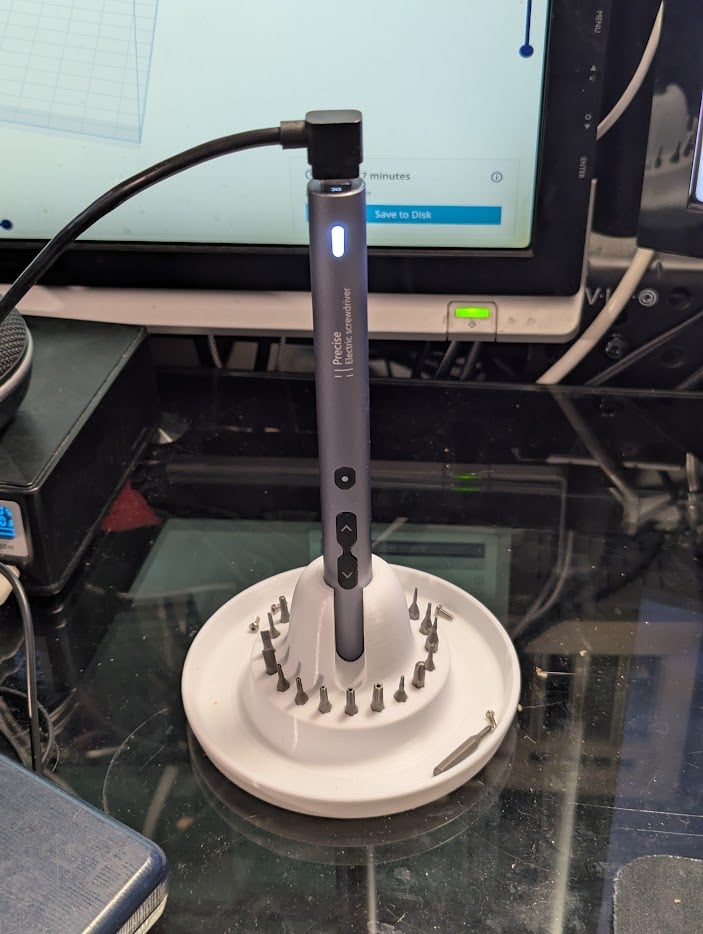

Could flip the driver 180 and put the charger in the print

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

Had this same thought. Maybe the cable channel could be the divider for separate screw trays.

What brand of driver?

Also get one of these, flip the driver over, and integrate the cable into the base.

Some amazon no name one. It's a 15.5mm diameter one.

Thats a brilliant idea and I'm ashamed I didn't think of it.

Here is the STL if anyone wants to remix it or whatever.

Might’ve been this one? I just searched for “Precise electric screwdriver” and found one that closely matches your picture.

That looks to be the one!

It'd be a good idea to post it to one of the websites that host 3d printing models (thingiverse, printables and so on) with a license so more people will have access to it. Good model and now I want one of these just because :)

stick a bearing where the driver sits and you could make a carousel

edit: you've already thought of that

Great minds! Appreciate the advice all the same.

It's definitely crying out for that ability. Maybe also with a little tab and ratchet system so it clicks as you spin 🤔

Man just shove that shit in your tweed overcoat where it belongs.