Maybe, but your examples aren’t repeatedly wetted and dried. Could the repeated cycles cause the particles to move deeper?

HewlettHackard

The illustrations seem to indicate that stains and dead microbes accumulate in the middle of the wood, deep below the surface. It would be interesting to slice an old wood cutting board in half and see the accumulated stains!

The science on plain wood being safe has been around for quite a while. I remember reading a study many years ago where some scientists mashed bacteria all over the surface of a wood cutting board, rinsed it, dried it, and then tried everything they could to get the bacteria to transfer to fresh meat (including trying to pound the meat into the board with a mallet) and the meat remained uncontaminated. So, it seems like the safest option is a single unglued plank of wood.

Glue joints don’t act like wood, so presumably that makes bamboo act less like plain wood safety-wise.

The problem with plastic is that the knife marks can retain bacteria (which, unlike wood, the plastic doesn’t kill).

Did you see the pictures in the article showing how stains disappear?

The article discusses glue joints. Did you make it through the whole article?

Tangential on the broad face would mean it’s flat sawn (plain sawn). Like how woodworkers care about tangential vs radial shrinkage of wood species.

I ended up choosing a CMT 24T ITK (thin kerf) blade, which worked fantastically.

Why not a 24t for ripping?

I’ve seen his recommendation too but that’s another 2x price jump over the price range I’m already trying to avoid!

I was misremembering because my block plane blade has multiple notches like this example. My larger planes don’t. Example blade: https://www.leevalley.com/en-us/shop/tools/hand-tools/planes/blades/117808-o1-stanley-block-plane-blades-made-by-veritas?item=05P3173

Does the blade have multiple notches to allow adjustment as you sharpen it? Are you using the notch that makes the blade shortest?

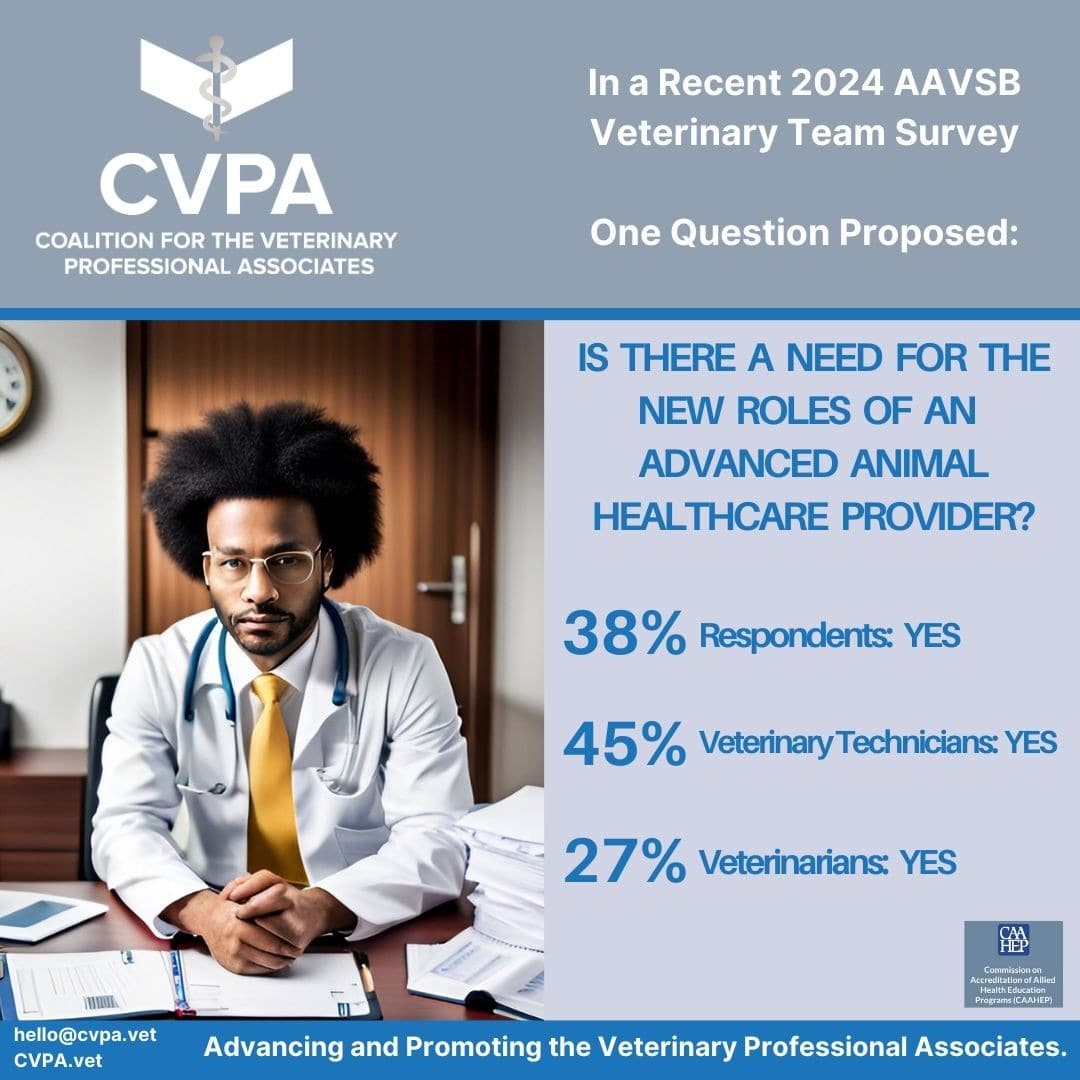

. And basically every professional association is strongly against it, for example:

. And basically every professional association is strongly against it, for example:

Unless I’m reading this too optimistically, it seems like recovering the resin just requires adding more of the original solvent, which sounds pretty good (as long as that solvent isn’t much nastier than a regular resin solvent).