Friends, fellows, lurkers, I have suffered a temporary field promotion. For the duration of this post you may address me as Major Aggravated.

I am building a sideboard/buffet/server/credenza/whatever you want to call a low cabinet for the dining room. Shaker style, mostly out of walnut. It features posts/legs at the corners to which the doors will be directly hinged, and the way I've designed this cabinet, the doors will be 3/4" thick, and sit 1/4" inset from the front of the leg. The leg is 1+3/4" thick, so there's 3/4" of leg inside the cabinet. There are other structural reasons I did it this way.

This complicates the matter of door hinges. I know of no pin-and-barrel hinge that will do the job, there's some weird specialty mortise mount concealed hinges that I'm just not sure if they'll work in this application, pivot hinges are too "too cheap for Ikea" for the project, and then there's European-style concealed cup hinges. I've known of these things for awhile but never really looked into them.

Until a couple weeks ago.

These hinges attach to the door with two screws and a big fuckoff hole. The offset from the edge might change slightly from project to project but the door half is pretty standard across the range.

On the cabinet side, there's like 8 different ways they can attach, depending on the anatomy of the cabinet, whether it has a face frame or not and if there are any offsets to consider.

The hinges actually come in two halves, the door side with the cup and the bracket for the cabinet side, and they clip together in a standard way, so that you can fuck up and mix and match parts in ways that won't work.

There isn't a European hinge made to attach to my cabinet as designed, because it sort of does and doesn't have a face frame simultaneously. The no-frame type wants to screw to a wall farther back than the leg, so that's a no-go, and the face mount type wants to attach to a face frame that is flush with the back of the door. They don't really make this easy to learn. They like to refer to the features of their hinges by marketing names that they never explain anywhere, and they don't really describe what they do. You just have to learn that "BLUMotion" means it has a damper through osmosis.

No website that sells these damn things organizes them well. Go shopping for wood screws, you get 90,000 results and you can then refine it by shank diameter, length, drive type, button or bugle head, self-tapping or no, self-countersinking or no, material/coating/finish etc. until you have 3 results, a 4-piece bag, a 50 count box and a 50 pound bucket.

Not these goddamn euro hinges. Nowhere that sells euro hinges in the Western hemisphere does it that way. It seems like a wholesaler buys parts from Blum, assembles them into kits, and these kits get dropshipped on eBay, Amazon, Rockler, the usual scumbags. So you don't get to query a database to narrow down your selection, you get to try to guess what search term will get you what you need and then look at the pictures, a practice that shall henceforth be known as "euro shopping."

You'll see the same marketing images on different platforms accompanied by different diagrams, dimensional drawings or installation instructions. Put it all together and they still don't tell you everything you need to know. I note that Rockler issues their own manuals for these things, not Blum's. Looking at Blum's publications, I can understand why.

I finally figure up what hinge set I think I need, given the little diagrams they provide. I order a few sets for my current and immediate future projects.

What arrives is not what I ordered.

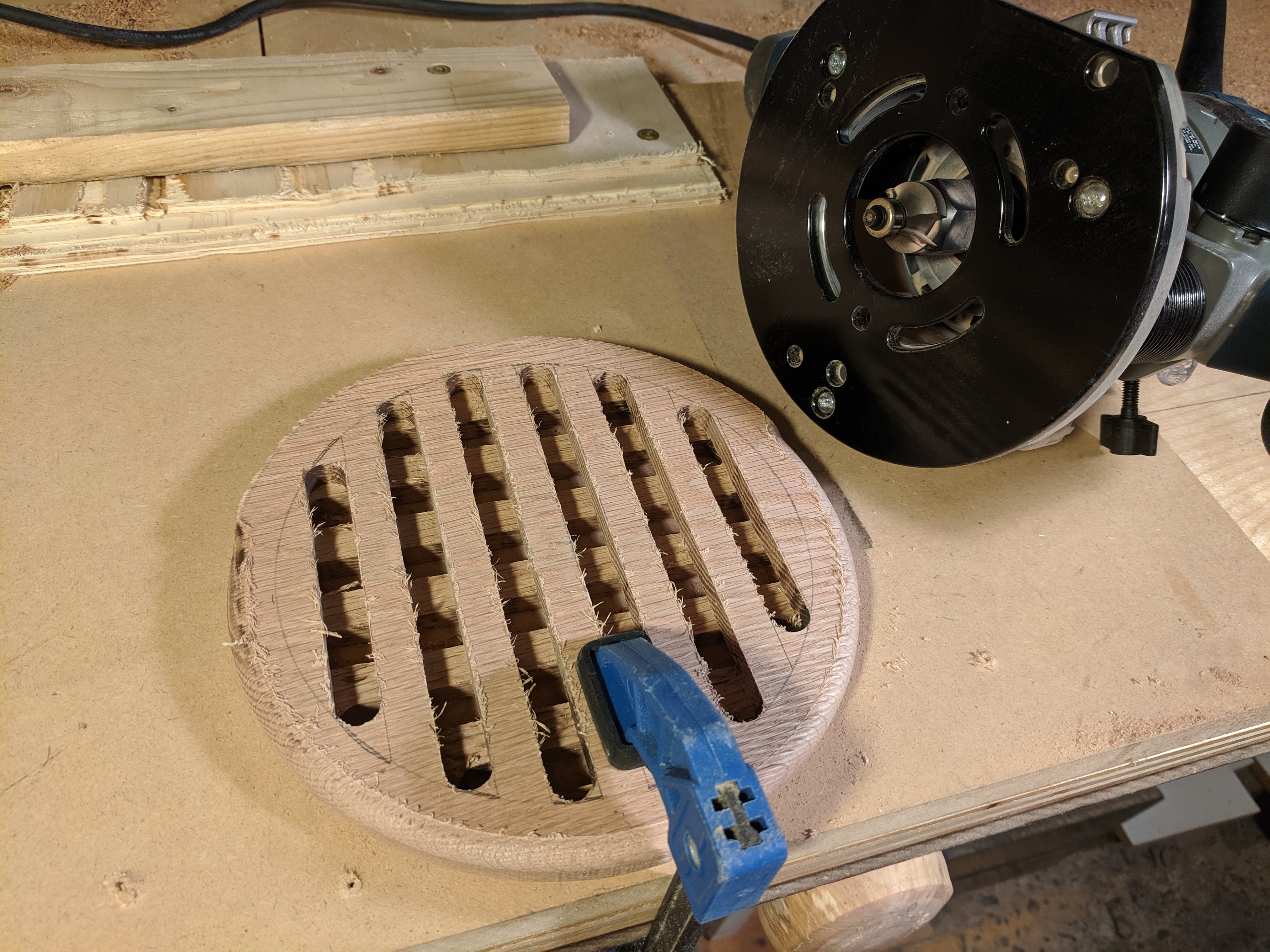

The door side, the actual hinge, looks right. But it comes with the wrong bracket. I see they sell just the brackets, I can order those and get them faster than processing a return. I order some of those. They fit. I make a model out of scrap to make sure they'll work, and the reveal between the frame and the door is like a quarter inch too big. Because it turns out the curvy bit of the hinge is 9.2 more bodacious than what I need, and you'd only learn that by carefully comparing the hinge in your hand with two diagrams in their catalog.

None of the components are stamped with a model or part number. Hell, the people selling these hinge sets don't say "Contents: 2x 640449 hinges, 2x 630449 brackets" so you can compare to Blum's catalog.

It's the smell of ten million monkeys fucking ten million footballs.