I've had fruit flies before that must have come in on some produce, have to be on it to clear them, leave out any fruit/veg scraps and they come out (out being tossed in the trash/green bin too, anything open air). Drop of dish soap, water and vinegar in a high walled glass or jar is the way to do it, I used balsamic but malt or wine vinegar works too, just leave that out and it'll do its job.

My current place we jokingly call the spider house, have a bunch of house spiders around (cats love them) and a few orb-weavers, garden and wolf spiders outside, pretty much anything native isn't a threat to humans or cats, they do a great job of taking out any pests, rarely see flies inside these days. Spiders and centipedes I'll leave alone, they're beneficial to have around.

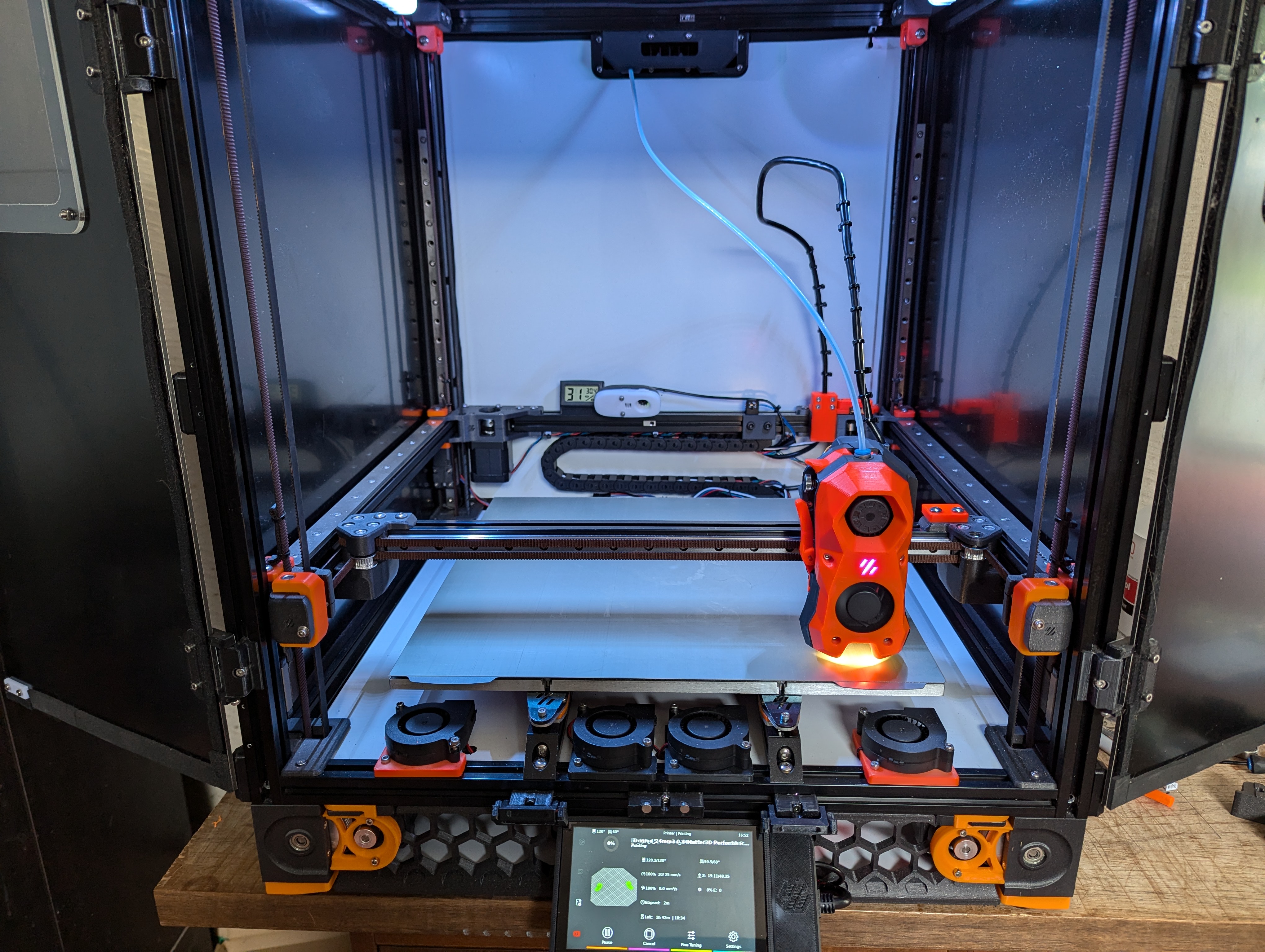

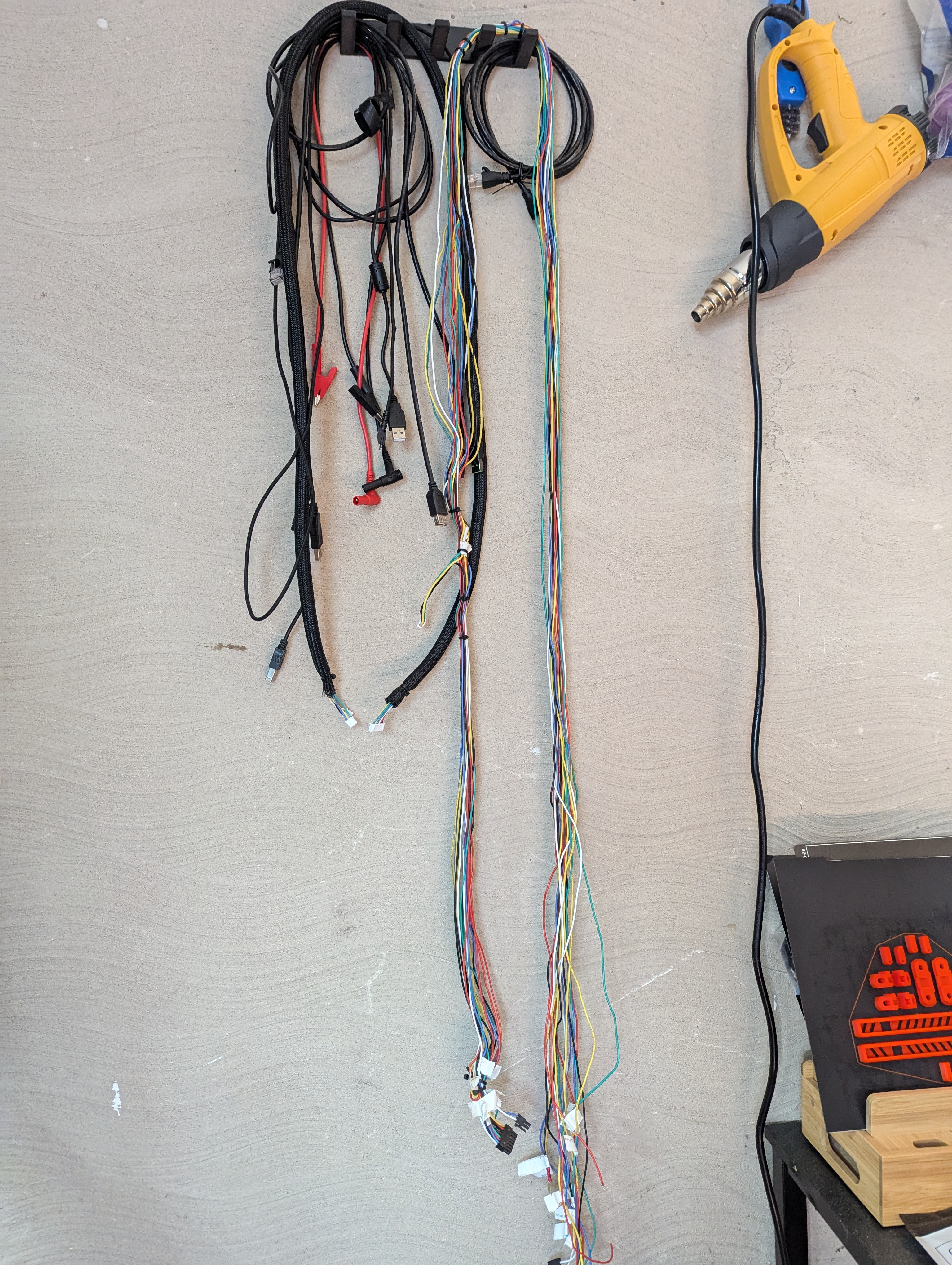

went for a usb can device over running can from the octopus pro, did want to swap the pro over to can as well but ended up keeping it the same instead of messing with reflashing firmware. Hotend has a little 3015 fan and a heatsink on the arm chip so cooling should be fine, looked up the datasheet and it's got a tjmax of like 120c and rated for ambient -40-80c so don't think I need to worry about it, if it's an issue I'll run a fresh air feed to it, will see how it likes abs in the summer shortly.

went for a usb can device over running can from the octopus pro, did want to swap the pro over to can as well but ended up keeping it the same instead of messing with reflashing firmware. Hotend has a little 3015 fan and a heatsink on the arm chip so cooling should be fine, looked up the datasheet and it's got a tjmax of like 120c and rated for ambient -40-80c so don't think I need to worry about it, if it's an issue I'll run a fresh air feed to it, will see how it likes abs in the summer shortly.

Grid infill is crossing, get a decent blob or buildup and you could have nozzle collision, I personally like gyroid but it is slower.

Had a similar failure on the mk3s, what does the belt tension test return? Stealth mode may help or be the cause, anecdotally I've seen mention of motor temps, the old rambo board running stock firmware they got toasty when printing in the enclosure in the summer, stealth helped me limp it along until I did a board swap and changed to klipper. I don't know if this is an issue with the mk4 as that's not using the older Rambo based boards, but something to consider as well, had it happen even after I did the first abs rebuild.

Edit: too tight can also cause issues, not necessarily skipping but having it trigger the virtual endstop, prusa has an article for troubleshooting layer shifting. Also probably with checking both axis to ensure they're smooth and consistent across travel, seen an over tight x carriage back cause too much resistance and have false triggers.